Automated Sample Preparation | Cut Impact, Save Time & Costs

Automation of the lab significantly reduces human errors that plague sample preparation outcomes. Manual processes handled by laboratory technicians are confronted with issues of consistency. Even highly qualified personnel have bad days or are absent from work due to illness. Such human factors impact reproducibility and translate to costly rework in metallography sample preparation workflows. Automated sample preparation is a crucial process for obtaining rapid results in the laboratory.

A comprehensive laboratory automation system offers a number of important benefits. Large-scale production is best served by fully automated grinding and polishing systems. Automatic cutting machines process several samples simultaneously with very little staff intervention. The advantages extend beyond reproducibility. These offerings provide streamlined procedures that require fewer experts. Greater precision, safety, and repeatability translate to greater certainty and reduced expenditures for your company.

What is Metallography? Definition, Techniques & Industrial Applications

This article demonstrates how sample preparation without an operator transforms metallography laboratories. We’ll cover all aspects from reduced training expenses to improved sample throughput. You’ll also hear about laboratory automation’s ROI and find out how these systems save money today and tomorrow.

Reducing Operator Dependency in Sample Preparation

Metallographic sample preparation remains a difficult task. Manual methods render results variable. Conventional metallography relies too heavily on operator technique to deliver precise, reproducible results—that causes numerous workflow bottlenecks.

Manual prep challenges in metallography workflows

The standard metallographic preparation practice allows operators to manipulate samples by hand against polishing surfaces. Direct control provides flexibility for making fine adjustments but results are variable. Manual polishing is labor-intensive, and results vary with operator skill and fatigue.

Manual preparation processes face several challenges:

- Sectioning damage: Incorrect cutting tools or methods produce thermal damage and deformation that alter the actual microstructure of the material

- Surface irregularities: Non-uniform pressure during polishing and grinding produces irregular surfaces

- Time management: Labs tend to polish for too long, believing additional steps will yield improved outcomes

Manual preparation also generates overpolishing issues. There are labs that employ as many as five polishing steps, mistakenly believing that this improves surfaces. Excessive polishing tends to round edges, push out harder components, and remove non-metallic inclusions. Fewer, directed polishing steps usually yield improved results in labs.

Impact of human error on reproducibility

Human mistakes significantly decrease measurement precision and result dependability. Tiny errors during metallographic preparation accumulate to significant interpretation issues.

Porosity measurement throughout preparation stages shows this clearly. Research proves apparent porosity can drop to one-third of its value in just the final preparation stages. This big change shows how preparation differences directly change quantitative measurements.

Damage recognition poses a further challenge. It is not simple to identify residual damage, particularly in complex structures, easily damaged components, or in failure analysis. The level of residual damage alters measurement outcomes considerably, and consistent preparation is therefore critical.

What is the Vickers Hardness Test? | Method, Applications &Advantages

Polishing defects also render results difficult to reproduce. Individuals tend to polish longer on soft cloths to remove visible damage. This practice generates polishing relief—sections that polish at different rates, producing differences in height that appear as dark lines under light microscopy. Such artifacts prevent precise measurement and analysis.

Training overhead and skill dependency

Laboratories require a large investment in training in order to achieve good metallography skills. Full training courses typically last several days. They encompass fundamentals such as sectioning, mounting, grinding, polishing, optical microscopy, etching, and hardness testing.

Advanced certification programs need students to finish structured courses in:

- Metallurgy basics and specimen preparation

- Microstructure interpretation

- Analytical methods

This training requires a great deal of time and funds. Yet even with training, automation provides critical advantages that skill alone cannot equal:

- Improved finish and flatness results

- Greater, more reproducible results

- Higher productivity with more specimens processed per shift

- No dependence on operator skill

Laboratory automation systems address these issues by normalizing the processes and eliminating operator variations. Automatic polishing systems process several samples simultaneously with programmable conditions for rotation speed, pressure, and polishing time. Such consistency benefits high-volume environments in which uniform and reproducible results are essential for dependable metallographic analysis.

Automation for Reproducible Metallographic Results

Recent automation technologies have transformed metallographic sample preparation. The developments have removed variability and increased consistency. Sophisticated systems now provide reproducible results with little or no human intervention, as compared to conventional methods.

Hands-off metallography using smart systems

Intelligent metallographic systems automate the entire preparation workflows today. The Velox 102 is a fully automated, end-to-end grinding and polishing solution that laboratories require for outstanding reproducibility and throughput. The system greatly enhances consistency among samples by reducing the risk of human error.

A technician needs less than 5 minutes to load consumables and insert specimen holders in these smart systems. The machine then works independently while the technician focuses on other tasks. This marks a fundamental change from traditional manual preparation methods.

These smart systems are equipped with amazing features:

- Programmable memory holds personalized workflows

- Automatic adjustment of parameters according to sample properties

- Combined cleaning functionality with ultrasonic or high-pressure capability

- Complete data logging to confirm and enhance processes

These systems change metallographic preparation from an operator skill-dependent art to a standardized, repeatable science.

Operator-free sample prep with closed-loop control

Closed-loop control systems mark the latest advancement in automated metallography. These systems monitor preparation parameters continuously and adjust automatically to maintain optimal conditions.

Velox 102 automatically adjusts force according to the number of specimens in the holder. This does away with manual force calculations and the need for methods in the database. The system also automatically carries out run-in procedures for new polishing surfaces. It determines if pre-dosing is necessary prior to commencement, which eliminates human attention.

Operator-free preparation with closed-loop control offers several benefits. The system dispenses with training, minimizes consumable waste due to optimized processes, and offers full documentation for quality assurance. Such systems generate comprehensive log files of processed specimen holders, methods applied, consumables used, and operating durations. This allows process standardisation that translates into more reproducibility and efficiency.

How to Prepare Metallographic Samples – Complete Step-by-Step Guide (With Expert Tips)

Boosting Throughput with Laboratory Automation Equipment

Metallography laboratories nowadays simply have to examine more samples with the same or fewer personnel. Modern equipment converts this dilemma into an opportunity by doing more with current staff levels.

High-volume laboratory automation for faster cycles

Automated metallography systems transform the landscape of traditional workflows. A manual sample requires 1-2 hours of preparation time, whereas automated systems finish the same in approximately 25-45 minutes. This is significant because it equates to a 60% increase in throughput, which allows laboratories to manage increasing workloads without increasing personnel.

The time saved at every phase says a lot:

- Reducing drops from 10-15 minutes to 5-7 minutes per sample through automation

- Mounting time decreases from 30 minutes to 10-15 minutes

- Grinding & Polishing time is cut down from 1-2 hours to 20-30 minutes

Laboratories that require high reproducibility usually select large laboratory automation volume equipment with programmable process controls and automated movement. Technicians can load several samples, program the whole preparation sequence, and attend to other duties as the processing occurs.

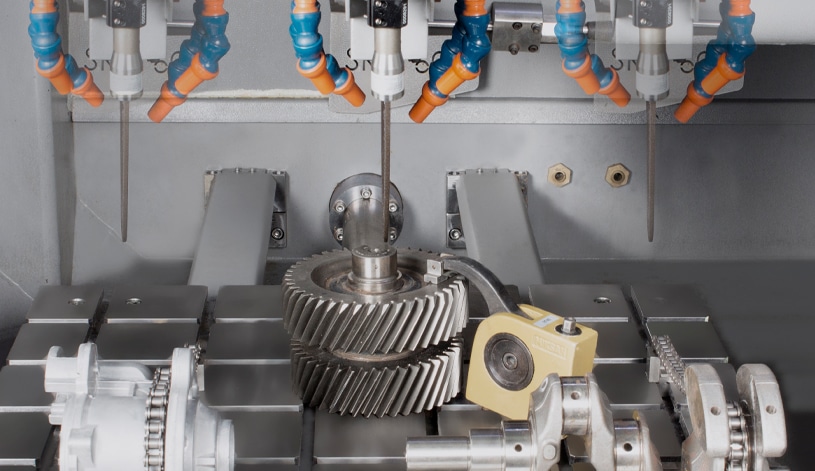

Cutting machine automation for batch processing

Manual operation is a thing of the past for today’s cutting machines. The Servocut 602 AX-R, for example, is a fully automatic 4-axis cut-off machine ideal for high-volume sample throughput laboratories. These machines are equipped with easy-to-use controls and a large automated rotary cutting table that enhances the sectioning procedure and eliminates re-clamping.

Automated cutting systems offer a number of advantages. Precise feed speed selection minimizes sample deformation and optimizes cutting angles. Integral recirculation systems maintain coolant flow to avert heat damage and remove cutting debris. Up to 99 different cutting operations can be saved by the operator, which saves repeat setup time.

Sample throughput optimization with minimal stops

Contemporary laboratories require fast and dependable methods of processing specimens with fewer individuals and less disruption. Tactical use of automation assists in optimising throughput successfully.

Servocut automatic metallographic cutting machine demonstrates this philosophy by various inherent intelligent features. The machine senses when cutting is complete and automatically stops while also withdrawing the blade. Closed-loop controls avoid overloading and safeguard motors and circuits against heat damage. Feed and cutting speeds can be different within the same cutting cycle.

Standardization and Data-Driven Process Control

Automated metallographic instrumentation offers standardization and data management benefits in addition to speed and repeatability. These capabilities transform the landscape of quality control by eliminating process variables and generating extensive data streams that propel ongoing improvement.

Audit trail generation and process traceability

Laboratory automation provides extensive audit trails that monitor all elements of sample preparation. Tamper-evident, computer-generated, time-dated records record user ID, date, time, and pre and post values when an individual creates, edits, or deletes an electronic record. The record has:

- All operator entries and actions

- Auto verification with target values

Using process data for predictive maintenance

Lab automation systems gather vast amounts of data that enable proactive maintenance approaches, which are their most beneficial aspect. Machine learning algorithms analyze the data to foresee equipment malfunctions before they occur.

The system employs IoT sensors for monitoring the condition of equipment, creates predictive models, and integrates with current maintenance systems. The critical equipment is first identified by the team, and then sensors are installed to monitor parameters such as vibration, temperature, and pressure. Maintenance is scheduled during planned downtime in this model rather than responding to failures. The outcome is less unexpected failure and little disruption in production.

Metallographic laboratories achieve improved process control, enhanced compliance documentation, and equipment performance optimization over time using these evidence-based methodologies.

Cost and Time Savings from End-to-End Automation

End-to-end automated systems provide outstanding economic returns to the metallography laboratory. Their benefits far exceed the scope and extent of original equipment investment and technical advantages that we have so far considered.

Laboratory cost reduction strategies through automation

Laboratory expenses are the largest expenditure in operating a laboratory. Automated metallographic systems address this issue by reducing the number of workers needed. Research indicates laboratories require 20-30% less full-time employees (FTEs) after automating.

Automated systems work around the clock without human limitations. Labs can boost their output by over 60% without adding more staff. This improved efficiency helps laboratories handle growing workloads without hiring more people – a huge advantage given how hard it is to find skilled metallographic technicians worldwide.

Consumable cost savings in labs via reduced rework

Automation cuts down on errors, which directly affects how much labs spend on consumables. Manual preparation often leads to mistakes and redoing work, wasting materials, reagents, and energy. Automated systems practically eliminate this waste by processing samples consistently.

Minor gains in consumable management translate into significant long-term savings. As one illustration, magnetic disk systems for polishing materials perform more effectively than conventional adhesive-backed alternatives. Magnetic systems allow you to change disks quickly without backing damage, whereas disposable PSA backings require total replacement. This is a cost-saver in the long run even though it costs more initially.

Return on investment in lab automation systems

Calculations of ROI for lab automation have to consider both short and long-term advantages. These investments return faster than you would think.

The payback calculation concentrates on three primary elements:

- Lower labor costs through better staff productivity

- Lower rework and consumable expenses

- Increased output without additional personnel

Most importantly, automation allows labs to utilize their personnel for more sophisticated analytical activity rather than repetitive manual tasks – an advantage that extends well beyond basic dollar calculations.

Automated sample preparation is transforming metallography laboratories seeking improved consistency, productivity, and cost-effective solutions. In this article, we examined how operator dependence causes significant challenges in conventional metallographic preparation. Manual operations introduce variability, regardless of the technician’s experience or expertise.

Thus, laboratory automation systems offer cogent solutions to these long-standing problems. Intelligent metallography systems manage the entire preparation process with very little human intervention. They convert what used to be an art relying on operator expertise into a standardized, reproducible science. Robotic grinding and polishing devices deliver consistent results. Closed-loop control systems monitor and modify parameters to achieve optimum outcomes.

The benefits in throughput are impressive. Automated systems finish sample preparation within 25-45 minutes, whereas it takes 1-2 hours if done manually. This is significant because it translates to a 60% increase in throughput. Laboratories are able to cope with increased demands without hiring additional personnel. Cutting machine automation also increases productivity by batch processing and programmable parameters that reduce repetitive setup time.

The financial argument for automation also holds water. Laboratories require 20-30% less full-time staff after the utilization of programmed systems. This results in significant annual labor savings. Reduced rework impacts consumable use and cost directly. Increased throughput capacity provides new revenue opportunities. These collective advantages guarantee fast return on investment even with initial equipment expenses.

Automated sample preparation provides improved reproducibility, enhanced efficiency, better standardization, and significant cost reductions. Metallography laboratories are under increasing pressure to process more samples with limited resources. Automation transforms this challenge into an opportunity for operational excellence and competitive advantage.

FAQs

Q1. What is the effect of automated sample preparation on laboratory costs? Automated sample preparation lowers laboratory costs substantially by saving on full-time personnel, rework and consumable costs, and improving throughput capacity without requiring extra personnel. Research indicates that laboratories can cut staffing requirements by 20-30% following automation, with considerable yearly labor savings.

Q2. What are the key benefits of automating metallographic sample preparation? Automating metallographic sample preparation offers several benefits, including improved reproducibility, increased efficiency, enhanced standardization, and significant time savings. Automated systems can complete sample preparation in about 25-45 minutes compared to 1-2 hours manually, representing a throughput increase of over 60%.

Q3. In what way does automation enhance metallographic result consistency? Automation enhances consistency through the removal of human variation from the preparation process. Intelligent metallography systems manage complete workflows with very little human interaction, treating every sample in exactly the same way. Such standardization converts metallographic preparation from an operator-dependent art form to a reproducible science.

Q4. Can automated systems handle complex metallographic processes? Yes, today’s automated systems can deal with complex metallographic processes. They have programmable controls for speed, pressure, and duration of different parameters. Closed-loop control is available in some systems that constantly monitors and makes adjustments to ensure optimal conditions are always present during the preparation process.

Q5. What is the role of data in automated metallographic sample preparation? Data is an important part of automated metallographic sample preparation. These systems create detailed audit trails for full process traceability and gather extensive data that aid proactive maintenance practices. This data can be utilized to foresee equipment failure, optimize performance, and maintain adherence to industry standards.