SERVOCUT 602 AX-R

PRODUCTS

SERVOCUT 602 AX-R

SERVOCUT 602-AX-R combines the most advanced cutting techniques in the same machine. Equipped with the large automated rotary table that eliminates re-clamping, saves time and provides maximum automation. With combination of all 4-axis, the cutting can be done in any possible position without re-clamping.

SERVOCUT 602 AX-R

4-Axis Multi-Target Automatic Cutting Machine

SERVOCUT 602-AX-R is designed for cutting complex shaped specimens in any angle without re-clamping.

• Equipped with 360° rotary table with servo motor drive

• Ability to cut specimens up to 20 different cutting lines in different angles

• Program memory for cutting lines and parameters for Multi-Target Cutting.

Servo motor driven rotary table allows very precise angle positioning. Save setup time by storing up to 20 cutting lines with different angles which can be recalled at any time for quick and easy loading. 4-axis cutting is the fastest way to reduce setups, boost throughput, and increase accuracy on complex parts.

BENEFITS

Metkon products optimize your sample preparation processes with high precision, efficiency, and ease of use.

4-Axis Cutting Capability with 360° Rotary Table

Achieve accurate angle adjustments with 0.1° precision, ideal for complex specimen cutting.

- Equipped with 360° rotary table (Ø710 mm) with servo motor drive.

- The angle of rotary table can be adjusted with 0.1° accuracy

- 4-axis cutting is the fastest way to reduce setups, boost throughput, and increase accuracy on complex parts.

- With combination of all 4-axis, the cutting can be done in any possible position without re-clamping.

TIME-SAVING AUTOMATED CUTTING

Eliminate re-clamping and store up to 20 cutting programs for faster workflows.

- Clamp-less Operation

- Ability to cut specimens up to 20 different cutting lines in different angles without unclamp, rotate and re-clamp.

- Eliminates multiple re-clamping, reduces setups and increases accuracy.

MULTI-TARGET CUTTING CAPABILITY

Cut up to 20 specimens simultaneously with high accuracy and effciency.

- Cut-off wheel moves on both X and Y-axes. It allows Multi Target Cutting Feature; several clamped specimens can be cut in one step.

- Up to 20 different specimens can be fixed on different position of table and can be cut automatically with same or different parameters in one cycle.

- All axes (X-Y-Z-R) driven by servomotors. This allows very precise positioning and fast movement.

OPERATOR-FRIENDLY DESIGN

Joystick control and a 10″ HMI touch screen o er intuitive and easy operation.

- All axes can be controlled with a joystick. It allows easy and fast positioning. Two hand operation for maximum safety.

- Extraordinary access for easy handling with sliding door and side openings.

- 10” coloured HMI touch screen and user-friendly so ware allows easy view and control of all steps. Up to 70 different cutting programs can be saved.

FEATURES

A wide product range, programmable controls, and durable construction meet all sample preparation needs.

MULTI TARGET CUTTING

Multi Target Cutting is unique and the most distinctive feature of SERVOCUT 602. Up to 10 different specimens can be fixed on different position of table and can be cut automatically with same or different parameters in one cycle. It provides fully automation for multiple specimens, reduces labor costs. It is optionally available.

EXTRA LARGE CUTTING CAPACITY!

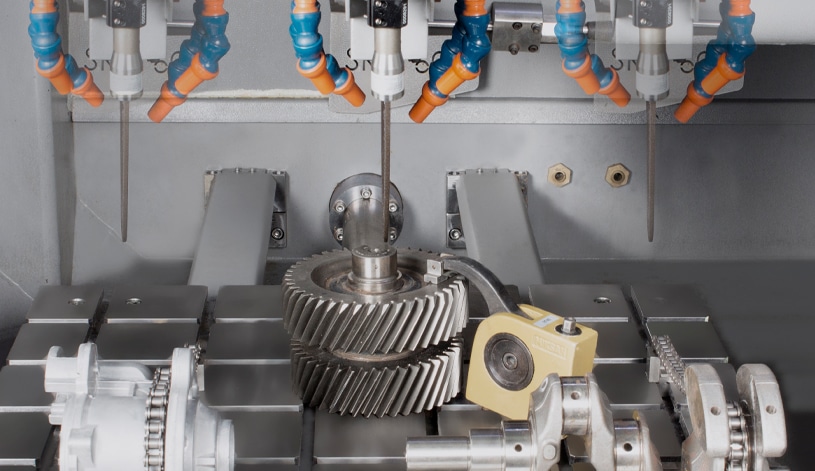

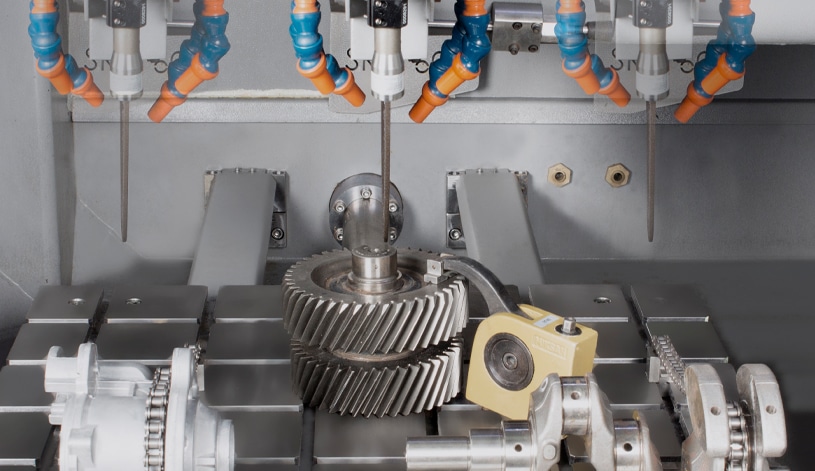

Very large cutting chamber and stainless steel table (772×710 mm) which provides easy placing of extra large and multiple specimens. Ability to work with up to Ø600 mm cut-off wheels. Large cutting capacity up to Ø225 mm for cylindirical specimens, 100Hx500D mm for rectangular specimens. Laser alignment unit is optionally available for precise positioning of the sample for the exact cutting line.

EXTREMELY POWERFUL CUTTING MOTOR!

It is very easy to cut hardest and largest specimens for SERVOCUT 602 thanks to powerful 15 kW cutting motor. Cut-off wheel speed can be adjusted from 600 to 2400 RPM to make possible to cut every kind of materials. Overload protection and unique belt protection systems allows maximum durability and safety.

AUTOMATIC MEASUREMENT OF CUT-OFF WHEEL DIAMETER

SERVOCUT 602 has technology to measure diameter of cut-off wheel automatically. Starting position is adjusted automatically according to wheel diameter. It does not matter how much cut-off wheel wears. It is also possible to keep peripheral wheel speed fixed. Motor speed is automatically adjusted according to wheel diamater thanks to automatic cut-off wheel diameter measurement technology. It does not matter how much cut-off wheel wears.

INSTAFEED CUTTING (AUTO FEEDRATE)

Feedrate is the most important factor when cutting specimen. High feedrate values may cause sample burning, excessive wheel wear, motor overload and even cut-off wheel breakage. Low feedrate values increase cutting time. With Auto Feedrate Cutting(Instafeed Cutting) method, feedrate is adjusted automatically to an optimum level according to motor load continuously. Thus cutting is completed in shortest possible time without burning specimen.

ADVANCED CUTTING METHODS

SERVOCUT 602 has many advanced cutting methods to overcome all difficulties of large, hard and complex shaped specimens. Optional Diagonal, Step and Segment Cutting methods make SERVOCUT 602 perfect choice for a broad range of heavy-duty cutting applications. Rapid Pulse Cutting feature reduces contact time and ensures maximum cooling of specimen. Table Oscillation Cutting feature minimizes the contact area to reduce the risk of specimen damage.

EASY OPERATION WITH TOUCH SCREEN AND JOYSTICK

A large colored 10″ HMI touch screen is used for operating machine. It has advanced software with very easy use. All cutting parameters [Wheel Speed, Feedrate, Travel, Cutting Modes, Starting Position, etc…] can be set and stored in memory under a specific program number. Wheel and table can be positioned easily via joystick in X-Y-Z axes.

EFFICIENT SAMPLE COOLING AND FILTRATION

Four cooling nozzles are positioned both right and left sides of cut-off wheel. Position of nozzles can easily be adjusted according to sample. Powerful pumps provides very high flowrate of cooling liquid. Thus, no burns occur on the specimen surface. Recirculating coolant tank has 200 lt capacity and it can be placed inside the cabinet of SERVOCUT 602. Optional level sensor always monitors the fluild level and inform operator when fluid level is low.

ROBUST CONSTRUCTION & HIGHEST SAFETY STANDARDS

SERVOCUT 602 is designed for 7/24 operation and low maintenance requirement. All mechanical parts assembled on robust steel construction to eliminate vibration and stretch. Long life reliable mechanical parts, Siemens PLC control unit and modern electronics allow 7/24 operation. SERVOCUT 602 has highest safety standards. It comply with CE, UL and CSA standards. Equipped with numerous safety components to guarantee maximum operator and machine safety.

AUTOMATIC LUBRICATION UNIT

An automatic lubrication unit is optionally available to minimize maintenance and shutdowns. All moving parts automatically lubricated without any operator intervention. There are liquid level sensor in the lubricant reservoir. If oil level is low, a message will appear on the HMI screen to inform operator to add oil.

AUTOMATIC CLEANING UNIT

Automatic cleaning unit is optionally available to keep cutting chamber clean without any effort. Two powerful spiral water nozzles spray the water on every corner of cutting chamber. Cleaning time can be set easily from operation menu on HMI screen.

FUMEFILTER, FUME AND MIST REMOVING UNIT

An advanced fume and mist removing unit is optionally available for SERVOCUT 602. It collects, filters and condenses the fume and vapor from the cutting chamber which generated during cutting operation. It does not allow intense smoke generation inside the cutting chamber and mist formation on glasses.

TECHNICAL DATA

Technical specifications compliant with international standards ensure reliable and consistent results.

| Order No | 14 87-AX-R |

| Model | 602-AX-R |

| Max. Cut-off Wheel Diameter | Ø600 mm |

| Max. Cutting Capacity, Ø | Ø225 mm |

| Max. Cutting Capacity, HxD | 100x500 mm |

| Z-Axis Travel, (mm) | 270 mm |

| Y-Axis Travel, (mm) | 560 mm |

| X-AxisTravel, (mm) | 520 mm (+/-10 mm) |

| T-Table Dimension, (mm) | Ø710 mm Rotary Table |

| Rotary Table Positioning Angle | 360° with 0.1° Accuracy |

| T-Slot dimension, (mm) | 18 mm |

| Cutting Motor Power (S1) | 15 kW |

| Variable Wheel Speed | 600-2400 RPM |

| Wheel Diameter Measurement | Standard |

| Constant Peripheral Wheel Speed | Standard |

| Cutting Feedrate, (μm/s) | 20-5000 μm/s |

| HMI Touch Screen Controller | 9.7 inch |

| Chop Cutting in Z- Axis | Auto |

| Table Feed Cutting in Y-Axis | Auto |

| Angle Cutting | Standard |

| Parallel Cutting in X-axis | Standard |

| Multi Target Cutting | Standard |

| Table Oscillating Cutting | Standard |

| Rapid Pulse Cutting | Standard |

| Smart Feed Control | Standard |

| StepCut; SegmentCut; DiagonalCut | Optional |

| Automatic Cleaning System | Optional |

| Central Lubricating System | Optional |

| Size, WxDxH, (cm) | 184x173x236 |

| Weight | 1600 kgs |

| Recirculation Cooling Unit | 200 lt |

BROCHURE

Explore our catalogue detailing the technical specifications and application areas of Metkon products.

GET YOUR BROCHURE FOR SERVOCUT 602 AX-R

Discover everything you need to know about the Servocut 602 AX-R with our comprehensive brochure.

VIDEOS

Watch our videos showcasing the features and usage of Metkon products in detail.