PRODUCTS

MICRACUT 152

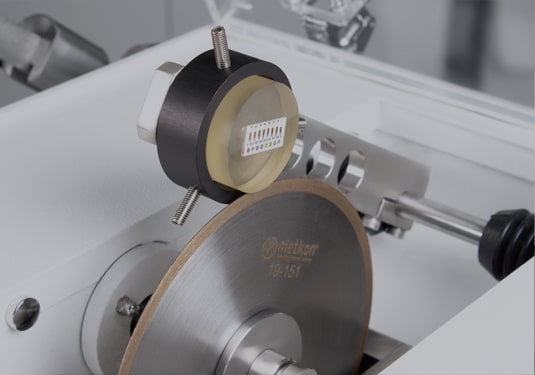

Metallographic Precision Cutter

MICRACUT 152 precision cutters are used for precise and deformation-free cutting of “Metals, Ceramics, Electronic Components, Crystals, Composites, Biomaterials, Sintered Carbides, Minerals, etc.” MICRACUT 152 has its place in virtually any metallurgical, geological, electronics, research, biomedical or industrial laboratory. The applications are endless. The cut surface is ready for microscopic examination with minimal polishing.

MICRACUT 152

MICRACUT 152 precision cutters are capable of cutting most materials such as, brittle or ductile metals, hard or soft metals, composites, ceramics, rocks, biomaterials, laminates, etc. They are designed for cutting all types of materials with minimal structural deformation. The structural integrity of the sample is maintained through MICRACUT 152’s design and operation. Additionally, low kerf-loss and sample holding versatility makes the MICRACUT 152 an essential part of the modern day laboratory.

• Easy to use control panel with ergonomic turn-knob

• Precise micrometer with digital readout

• Gravity feed system

• Automatic stop at the end of cut

• Transparent protection hood with magnetic safety switch

• Inbuilt recirculation coolant tank

BENEFITS

Metkon products optimize your sample preparation processes with high precision, efficiency, and ease of use.

COMPACT, PRECISE AND HIGH TORQUE CUTTING MOTOR

Transparent cover

- Equipped with a compact 100 Watt brushless DC motor, which allows quite and precise operation

- Ability to set disc speed from 100 RPM to 1500 RPM.

- High torque at each speed range.

OPERATOR COMFORT

- Modern-looking touch pad controls with ergonomic turn knob allows fast and easy setting of wheel speed and increases productivity.

- At the end of the cut, the motor automatically stops and an audible signal notifies the operator.

- Compact design with the integrated recirculation cooling unit. Therefore, you do not need any extra space in your lab.

FEATURES

A wide product range, programmable controls, and durable construction meet all sample preparation needs.

COMPACT AND PRECISE!

MICRACUT 152 is designed for cutting all types of materials with minimal structural deformation. The cut surface is ready for microscopic examination with minimal polishing. Equipped with a compact 100 Watt brushless DC motor, which allows quite and precise operation. Ability to set disc speed from 100 RPM to 1500 RPM. High torque at each speed range. Ability to use very thin cut-off wheel up to Ø175 mm diameter, under 1 mm thickness.

GRAVITY FEED CUTTING AND AUTOMATIC STOP

By the help of gravity feed mechanism, the sample can be feed towards the cut-off wheel with constant and exact load. This provides a very precise cutting surface. No manual feeding by hand is required. At the end of the cut, the motor automatically stops and an audible signal notifies the operator.

HIGH PRECISION SAMPLE POSITIONING

Equipped with a high precision micrometer with digital readout. The digital micrometer enables the operator to set the cutting witdh with a resolution of 1 micron. The digital micrometer is interchangable and the customer can mount other types of micrometers if and whenever required.

SIMPLE CONTROLS

Modern-looking touch pad controls with ergonomic turn knob allows fast and easy setting of wheel speed and increases productivity.

INBUILT COOLANT TANK

A 1 liter capacity coolant tank is located inside the machine. No external recirculation system is required. It does not take up extra space in your laboratory.

CUTTING TABLE ATTACHMENT

The optional Cutting Table Attachment transforms MICRACUT 152 into a PCB cutting saw. It can be simply mounted on MICRACUT 152 in seconds and fixed with strong magnets. You do not need to purchase a second machine to cut flat specimens like PCB.

TECHNICAL DATA

Technical specifications compliant with international standards ensure reliable and consistent results.

| ORDER NO | 16 05 |

| MODEL NO | MICRACUT 152 |

| Disc Diameter, mm | Ø175 mm |

| Cutting Capacity, mm | Ø50 mm |

| Cutting Motor Power, W | 100 W |

| Disc Speed, RPM | 50 - 1500 RPM |

| Cutting Method | Chop |

| Parallel Cutting in X-Axis | Yes |

| X-Axis Positioning, mm | 25 mm |

| Cooling Unit, lt | 850 ml (integrated) |

| Dimensions, WxDxH, (cm) | 40 x 41 x 36 |

| Weight, kgs | 28 kgs |

BROCHURE

Explore our catalogue detailing the technical specifications and application areas of Metkon products.

GET YOUR BROCHURE FOR

MICRACUT 152

Discover everything you need to know about the Micracut 152 with our comprehensive brochure.

VIDEOS

Watch our videos showcasing the features and usage of Metkon products in detail.