Knowledge

KNOWLEDGE

KNOWLEDGE

We provide comprehensive resources on metallographic analysis and materials science. Explore topics ranging from sample preparation techniques to microscopic examinations.

SAMPLE PREPARATION

Metallography is the science of revealing and evaluating the internal structures of materials. It is one of the most important methods of materials research today, indispensable to the scientist as well as to the engineer.

More recently, advanced materials such as high tech metal alloys, ceramics, composites and polymers have appeared which made metallography become an increasingly vital part of modern industry.

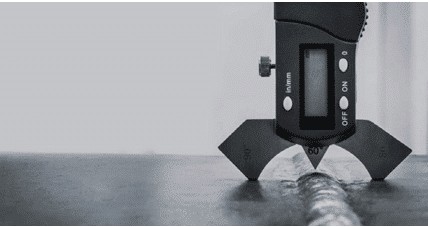

CUTTING TECHNIQUES

The first step in preparing a specimen for metallographic or micro structural analysis is to locate the area of interest. Sectioning or cutting is the most common technique for obtaining this area of interest. Proper sectioning guarantees minimal micro structural damage. Excessive subsurface damage and damage to secondary phases (e.g. graphite flakes, nodules or grain pull-out) should be avoided.

MOUNTING METHODS

Following cutting or sectioning the specimen is typically mounted. Mounting provides the following advantages:

• Convenient means to hold the specimen

• Provides a standard means to mount multiple specimens

• Protects edges

• Provides proper specimen orientation

• Provides a means to label and store the specimens

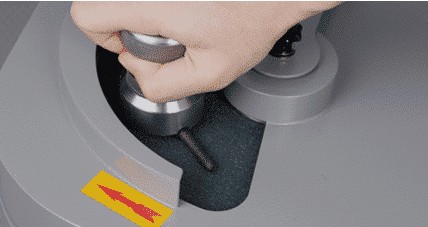

GRINDING & POLISHING

The purpose of the grinding step is to remove damage from cutting, planarize the specimen(s), and to remove material approaching the area of interest.

The most common metallographic abrasive used is Silicon Carbide – SiC. It is an ideal abrasive for grinding because of its hardness and sharp edges. For metallographic preparation, SiC abrasives are used in coated abrasive grinding papers ranging from very coarse 60 grit to very fine 2500 grit sizes. Some of the application procedures are given below.

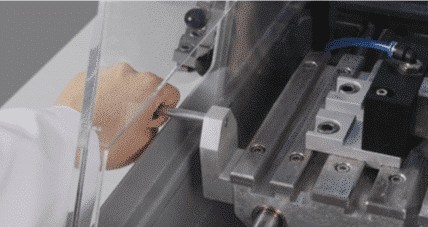

ELECTROLYTIC SAMPLE PREPARATION

Electrolytic polishing is the best way to polish very soft materials which are prone to smearing and deformation. It can be easily applied to objects of complex shape.

Materials that work well for electropolishing or etching include soft austenitic stainless steels, aluminum and aluminum alloys, copper and copper alloys, among others.

ETCHING

Etching is performed using a wide range of chemical solutions that vary depending on the material and the parameters to be examined. In fact, even for a single type of material, multiple etching solutions may be available. A technical expert can formulate new solutions by applying their knowledge of materials and chemistry. Some solutions are quite simple, while others are complex and contain strong chemicals (acids or alkalis). Therefore, laboratories must be well-ventilated, and precautions should be taken to avoid inhaling the solution vapors.

HARDNESS TESTING

Hardness testing is crucial for determining the mechanical properties of materials. At Metkon, we offer micro and macro hardness testing devices suitable for both laboratory and production environments.

MICROSCOPY TECHNIQUES

Microscopes with different magnification and imaging techniques, ideal for detailed examination of the surface and internal structure of materials. Various models are available for laboratory and industrial applications.

IMAGE ANALYSIS

Software and hardware solutions for digital analysis of microscope images. Used for measuring material properties, particle analysis and other applications. Image analysis software provides accurate and repeatable results.

WELD INSPECTION

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the work pieces and adding a filler material to form a pool of molten material (the weld pool) that cools to become a strong joint, with pressure sometimes used in conjunction with heat, or by itself, to produce the weld.

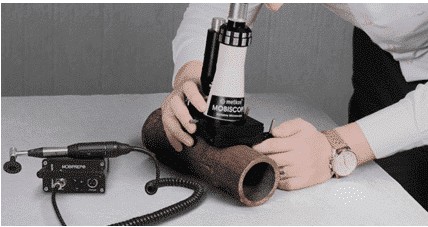

IN SITU METALLOGRAPHY

Field metallographic procedures are performed “on location” or in the “field” on components that are too large to bring to the metallographic laboratory. Generally, these components are still being used in service or must be returned to service and cannot be destructively sectioned or physically altered. Field metallography is also called in situ metallography, and it is sometimes called nondestructive metallography.

GEOLOGY

Petrology includes the subdisciplines of experimental petrology and petrography.

Experimental petrology involves the laboratory synthesis of rocks for the purpose of ascertaining the physical and chemical conditions under which rock formation occurs.

SPECTROSCOPY

Optical emission spectrometry (OES) using arc and spark excitation is the preferred method to determine the chemical composition of metallic samples. This process is widely used in the metal making industries, including primary producers, foundries, die casters and manufacturing. Due to its rapid analysis time and accuracy, Arc/Spark OES systems are most effective in controlling the processing of alloys.

ARTICLES

Unlock deeper knowledge in metallography with our exclusive article series. Written by our in-house application experts, each article bridges the gap between hands-on practice and cutting-edge research. Whether you are refining your sample preparation process or exploring new techniques, our content is designed to inspire precision, performance, and progress.

Get a hands-on training tailored to enhance your team’s capabilities. Explore the full potential of our expertise with dedicated, customer-focused solutions!

WHAT OUR CUSTOMERS SAY ABOUT METKON