You may also know that a standard petrographic thin section is only about 30 µm thick–one-third as thick as a HUMAN hair. At this exact thickness, light can travel through the darkest minerals, unlocking a subvisible world of colors, structures, and textures unseen with the naked eye. We’ve discovered that learning thin section preparation is […]

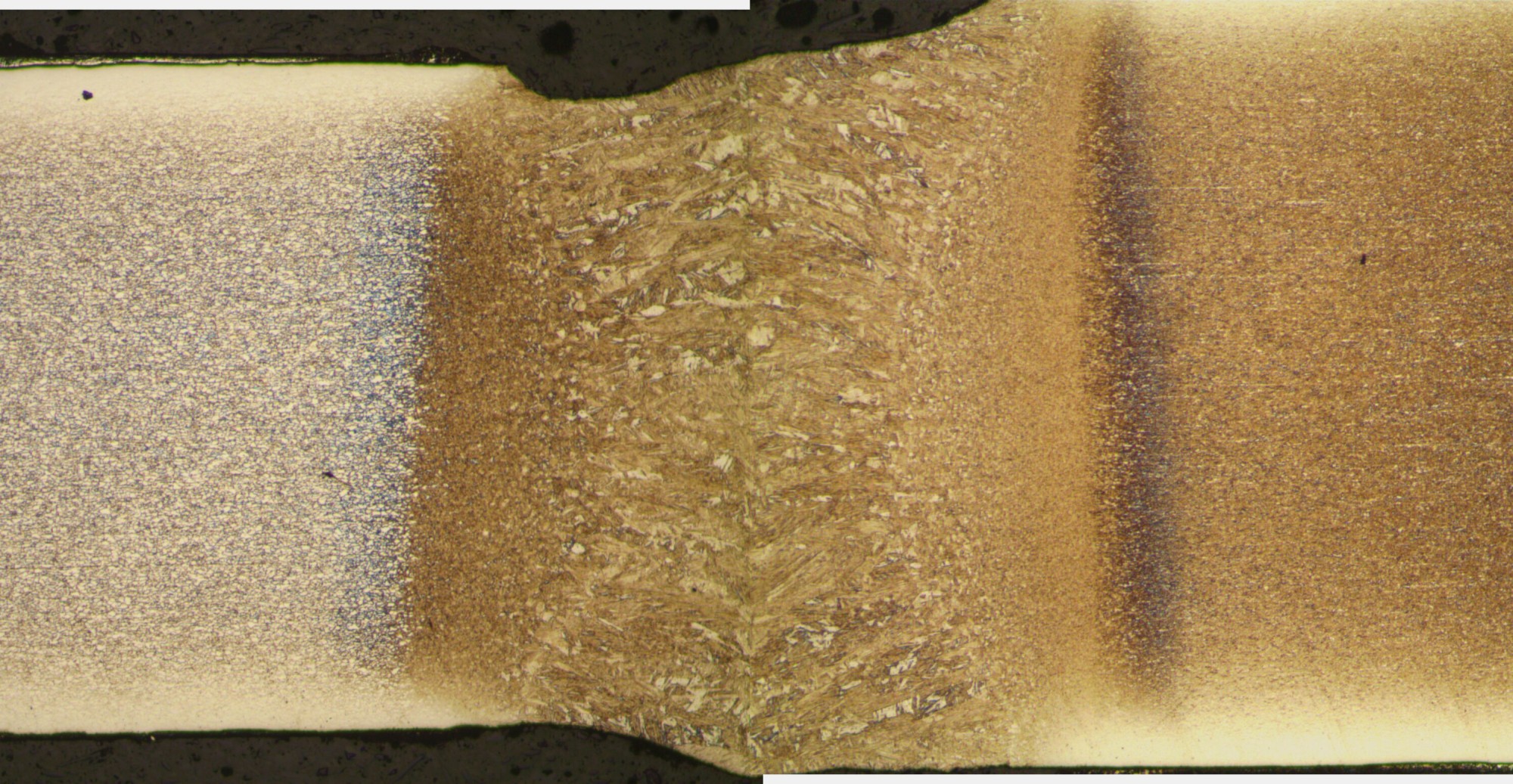

Weld inspection techniques are the backbone of structural reliability in industries where precision and accuracy cannot be derailed. Aerospace, infrastructure, and energy industries demand flawless welds – any defect can result in catastrophic outcomes and gigantic operating losses. Metkon provides specialized sample preparation solutions that ensure accurate weld quality determination via reliable metallographic analysis. Weld […]

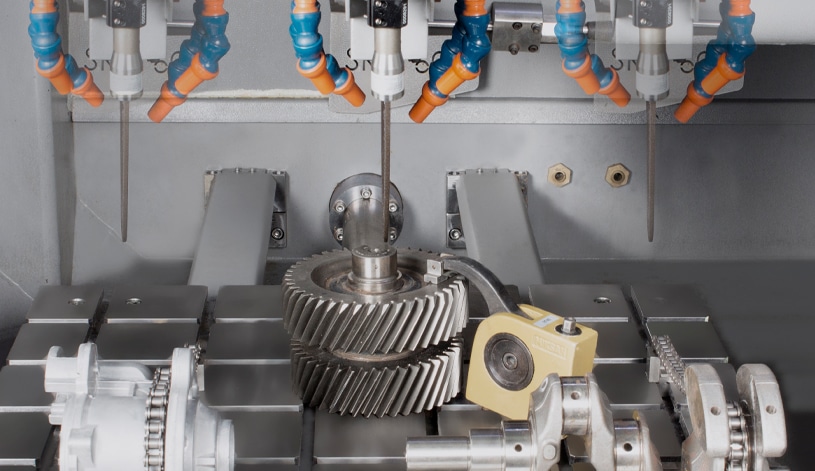

Automation of the lab significantly reduces human errors that plague sample preparation outcomes. Manual processes handled by laboratory technicians are confronted with issues of consistency. Even highly qualified personnel have bad days or are absent from work due to illness. Such human factors impact reproducibility and translate to costly rework in metallography sample preparation workflows. […]

The metallographic cold mounting process represents a critical step in proper sample preparation for materials analysis. Achieving perfect metallographic samples can be challenging, especially with heat-sensitive materials that would otherwise deform or alter under traditional hot mounting methods. We’ve found that mastering cold mounting techniques is essential for preserving the true microstructure of delicate specimens, […]

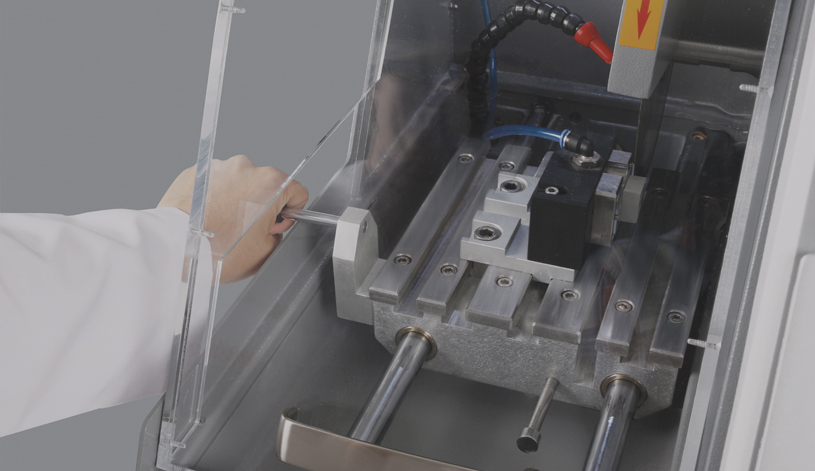

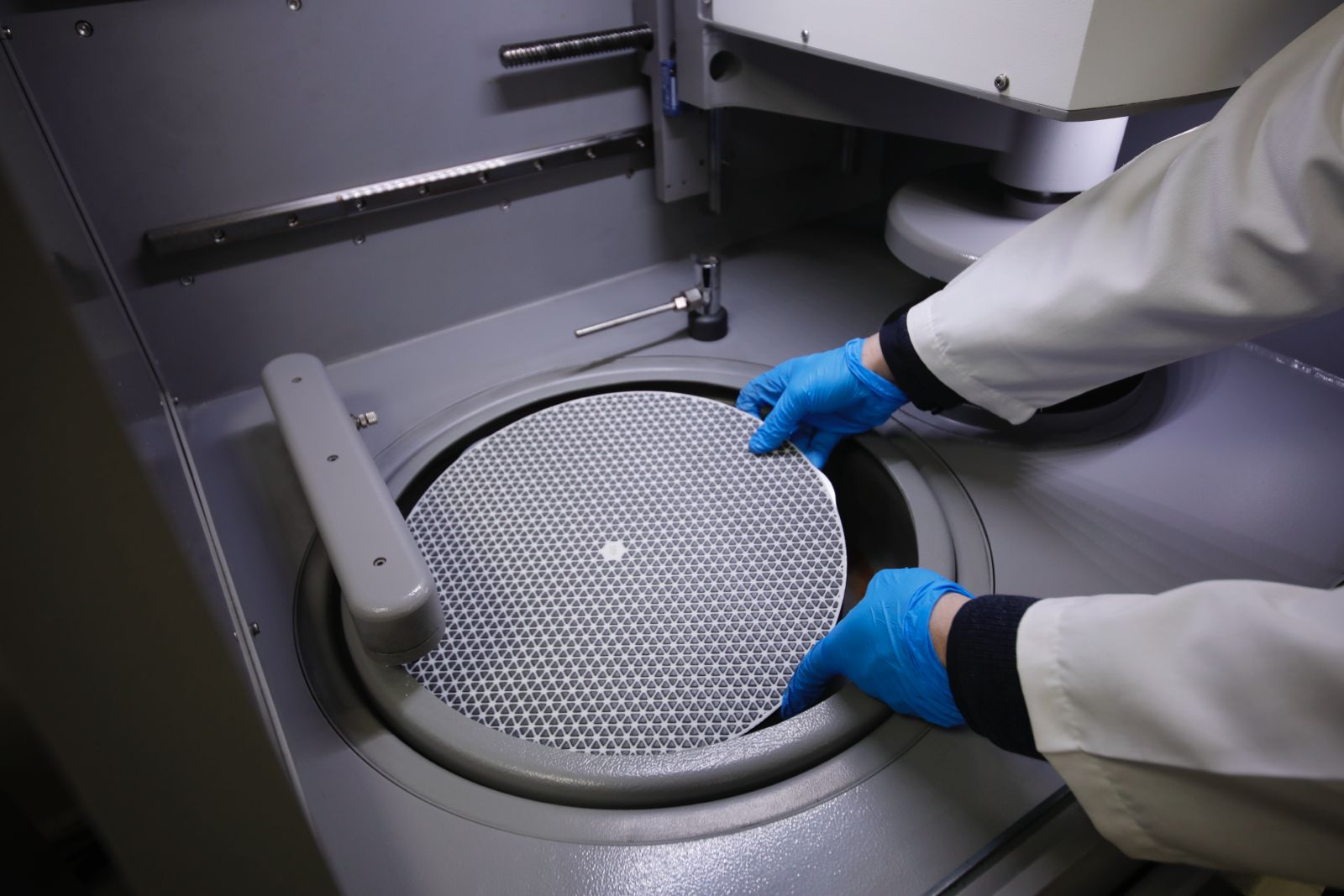

Did you know that over 80% of metallographic analysis errors are due to improper sample mounting? The metallographic hot mounting press remains one of the most significant pieces of equipment in any materials testing laboratory, directly affecting the quality and validity of microstructural examinations. When we prepare metallographic specimens, mounting well paves the way for […]

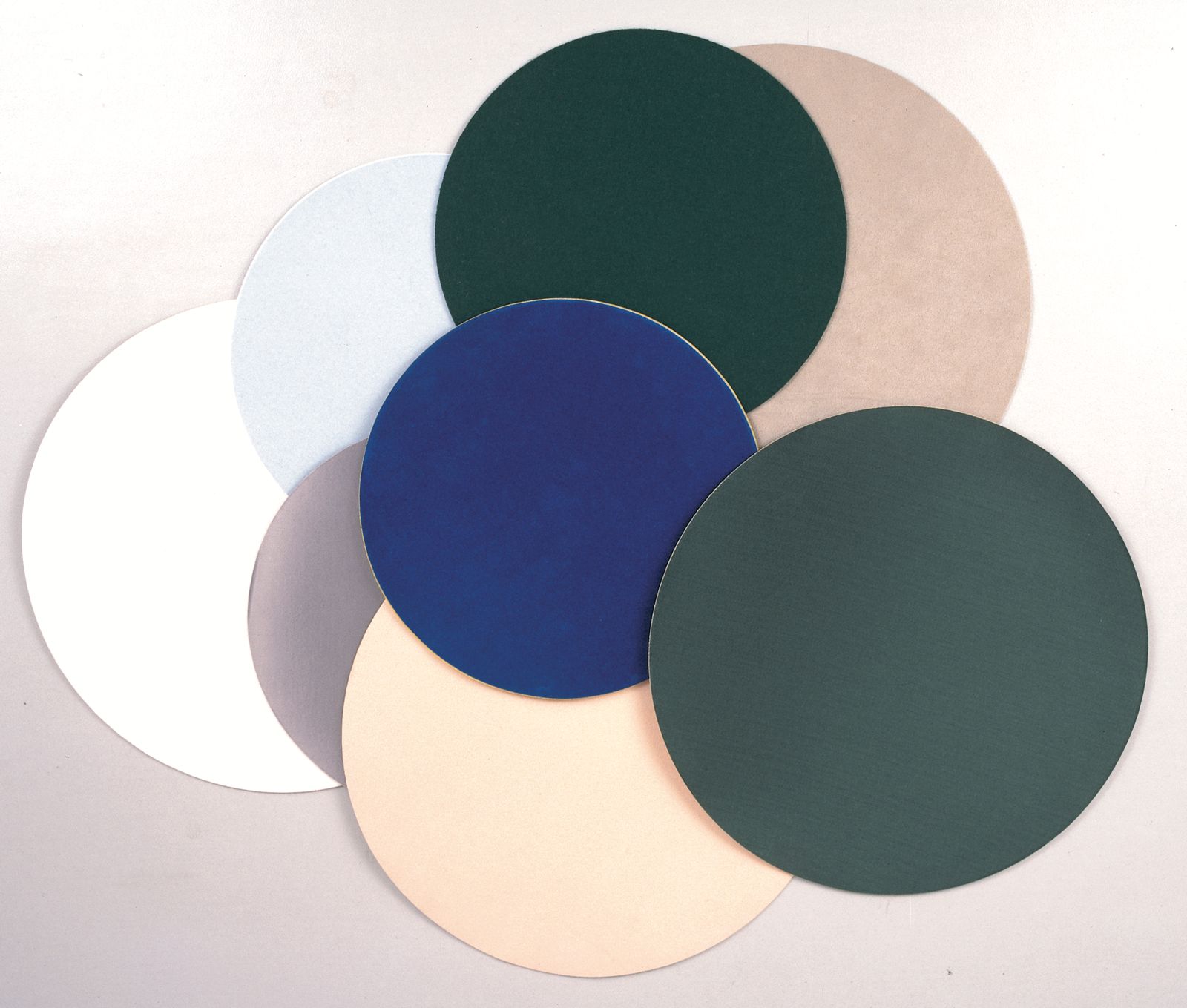

Have you ever had difficulties obtaining that perfect mirror finish on your metallurgical samples? Metallographic polishing is an art and a science that can either make or break your material analysis results. In our lab, we’ve discovered that as much as 80% of microstructural analysis errors are due to incorrect sample preparation techniques. Achieving a […]

Metallographic grinding remains the secret to effective microstructural analysis, yet labs get bogged down in inconsistent results and sample defects. Poor grinding procedures can render your entire analysis useless, creating misleading artefacts and wasting valuable research time. We’ve observed that even experienced metallographers tend to overlook important grinding parameters that make a significant difference to […]

The right metallographic cutting machine can mean the difference between perfect samples and unusable specimens. Lab professionals often struggle with burn marks, micro-cracks, and deformation. These problems compromise analytical results and waste both time and materials. Your metallographic sample preparation success depends on effective cutting techniques. The final results depend heavily on your choice of […]

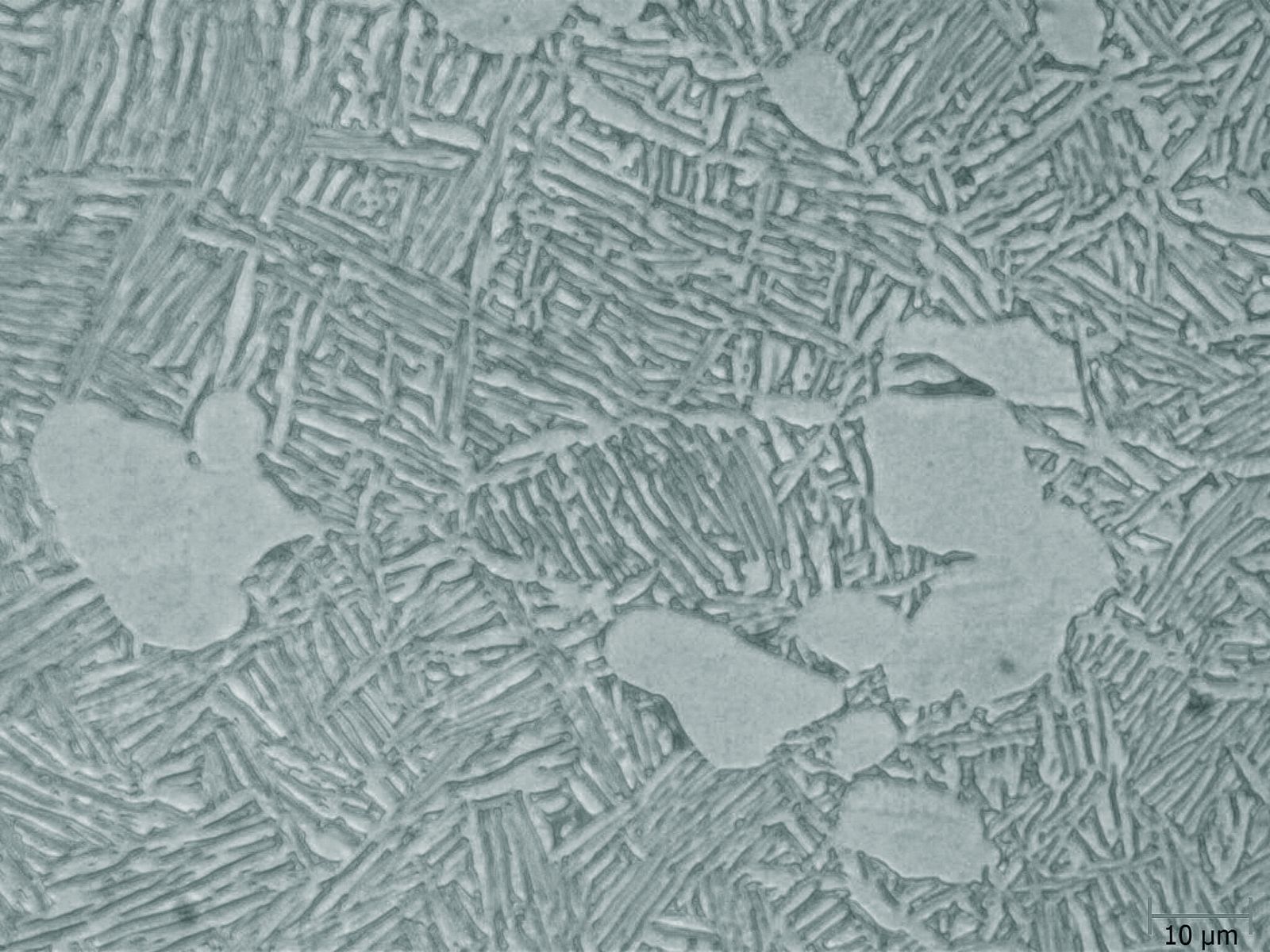

Metallographic etching reveals concealed microstructures in metals that recount the entire tale of material performance and properties. This essential technique is utilized daily in materials laboratories. The procedure brings to light grain boundaries, phases, and inclusions that would otherwise remain invisible. Even the most sophisticated microscopy cannot discern important microstructural details without etching. Such details […]

Correct materials analysis and characterization relies on correct metallographic sample preparation. Improper preparation can result in inaccurate results that misrepresent a material’s actual microstructure. Certain materials pose special problems in preparation. As an example, magnesium alloys are difficult to prepare since their low matrix hardness and harder precipitate phases cause relief problems. Additional safety considerations […]

- 1

- 2