When we combined our knowledge and enthusiasm with our imagination

and courage, a quarter-century success story emerged.

Founded 25 years ago, Metkon as a young and dynamic company

had delivered more than 20.000 instruments globally. We offer our

expertise and know-how to our customers worldwide to enable them

reach the "True and Excellent Sample".

We thank to our customers, employees, suppliers and partners.

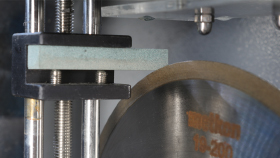

MICRACUT 202 precision cutters are capable of cutting most materials such as, brittle or ductile metals, hard or soft metals, composites, ceramics, rocks, biomaterials, laminates, etc. They are designed for cutting all types of materials with minimal structural deformation. The structural integrity of the sample is maintained through MICRACUT 202's design and operation. Additionally, low kerf-loss and sample holding versatility makes the MICRACUT 202 an essential part of the modern day laboratory. The cut surface is ready for microscopic examination with minimal polishing.

• Modern and sturdy design

• Extraordinary access for easy handling

• Ergonomic joystick control offers excellent application versatility

• Programmable with colored HMI touch screen controls

• Automatic cut-off wheel positioning

• Inbuilt recirculation coolant tank

| Order No | 17 07 | 17 07-AX |

| Model | 202 | 202-AX |

| Disc Diameter, (mm) | Ø200 mm | Ø200 mm |

| Cutting Capacity, ø (mm) | Ø75 mm | Ø75 mm |

| Cutting Capacity, # (mm) | #50x175 mm | #50x175 mm |

| Z-Axis Movement | Automatic | Automatic |

| Y-Axis Movement | Automatic | Automatic |

| X-Axis Movement | - | Automatic |

| Z-Axis Range (mm) | 45 mm | 45 mm |

| Y-Axis Range (mm) | 210 mm | 210 mm |

| X-Axis Range (mm) | - | 60 mm |

| X-Axis Resolution, mm | - | 0.014 mm |

| Table Feed Speed, (μm/s) | 5 - 5000 μm/s | 5 - 5000 μm/s |

| Thin Section Grinding Feature | Yes | Yes |

| Table Dimensions, mm | 365 x 205 mm | (305+60) x 205 mm |

| T- Slot, mm | 12 | 12 |

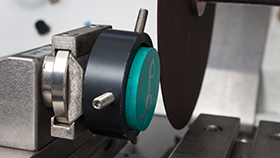

| Rotary Clamping Device | Yes | Yes |

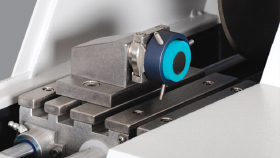

| Pulse Cutting | Yes | Yes |

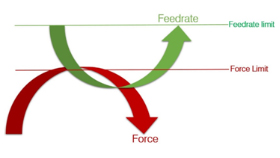

| Automatic Feedrate | Yes | Yes |

| Cutting Motor Power, (kW) (S1) | 1.1 kW | 1.1 kW |

| Disc Speed, (RPM) | 100 – 5000 RPM | 100 – 5000 RPM |

| Cooling Unit, (lt) | 9 lt (integrated) | 9 lt (integrated) |

| Joystick | Yes | Yes |

| HMI Touch Screen, (inch) | 7" | 7" |

| Program Capacity | 99 | 99 |

| Illumination | LED | LED |

| Laser | Yes (Optional) | Yes (Optional) |

| Dressing During Cutting Operation | Yes (Optional) | Yes (Optional) |

| Motor Drive System | Direct Drive | Direct Drive |

| Dimensions, WxDxH, (cm) | 74 x 75 x 64 | 74 x 75 x 64 |

| Weight | 150 kgs | 150 kgs |

| Accessories for MICRACUT 202 | |

| GR 0115 | Laser alignment unit for MICRACUT 202 |

| (To be ordered simultaneously together with the machine order) | |

| GR 0412 | Dressing Unit for MICRACUT 202 |

| YM 1590-00 | Dressing Stone |

| Clamping Tools for MICRACUT 202 | |

| GR 0825 | Manual X-axis positioning unit for specimen vises with dovetail plates (0-20 mm) |

| GR 0547 | Stand for specimen vises with dovetail plates. |

| GR 0826 | Stand with rotation for specimen vises with dovetail plates |

| (To be ordered simultaneously together with the machine order) | |

| GR 0548 | Quick acting clamping vise assembly for MICRACUT 202 |

| GR 0667 | Compact Vise Assembly, Spring Loaded, for MICRACUT 202 (Stainless Steel) |

| 15 05 | KKP 040 Vertical Clamping Device, with clamp. shoe, for MICRACUT 202 |

| GR 0551 | Quick Clamping Vise for longitudinal sectioning of bolts and fasteners |

| Specimen Vises for MICRACUT 202 | |

| GR 0210 | Universal Specimen Vise for MICRACUT 200-S/ 202 |

| GR 0400 | Universal Specimen Vise |

| GR 0401 | Specimen vise with double parallel vice for long specimens. |

| GR 0402 | Specimen vise for round and mounted specimens, ø32mm. |

| GR 0403 | Specimen vise for irregular shaped specimens. |

| GR 0404 | Specimen vise for adhering specimens. |

| GR 0405 | Specimen vise for biomedical samples. |

| GR 0430 | Specimen vise (teardrop shape) for specimens ø18-40mm. |

| GR 0431 | Specimen vise (teardrop shape) for specimens ø5-20mm. |

| GR 0434 | Specimen vise for round cylindrical specimens (max. up to 40 mm dia.) |

| GR 0453 | Fastener vise for longitudinal sectioning of screws, fasteners tubes, etc. from 12 to 45 mm in length |

| GR 0410 | Set of Flanges, ø75 mm, suitable for 12,7 and 25,4 mm arbor dias. |

| GR 0411 | Set of Flanges, ø100 mm, suitable for 12,7 and 25,4 mm arbor dias. |

| Spare Part Kit for MICRACUT 202 | |

| GR 1961 | Recommended Set of Spare Parts, MICRACUT 202 |

| Abrasive Cut-off Wheels for Precision Cutting (Pack of 10) | ||

| TRENO-HP | 18-150 | Ø 150 mm, for Non-Ferrous, Stainless steels |

| TRENO-MP | 18-151 | Ø 150 mm, for medium and hardened steels |

| TRENO-HP | 18-200 | Ø 200 mm, for Non-Ferrous, Stainless steels |

| TRENO-MP | 18-201 | Ø 200 mm, for medium and hardened steels |

| Diamond Cutting Discs (1 pc) for Precision Cutting | ||

| DIMOS | 19-100 | ø 100 Diamond Cut-off wheels (Metal Bonded, high conc.) |

| DIMOS | 19-125 | ø 125 Diamond Cut-off wheels (Metal Bonded, high conc.) |

| DIMOS | 19-130 | ø 125 Diamond Cut-off wheels (Metal Bonded, low conc.) |

| DIMOS | 19-126 | ø 125 Diamond Cut-off wheels (Resin Bonded, high conc.) |

| DIMOS | 19-150 | ø 150 Diamond Cut-off wheels (Metal Bonded, high conc.) |

| DIMOS | 19-157 | ø 150 Diamond Cut-off wheels (Metal Bonded, low conc.) |

| DIMOS | 19-151 | ø 150 Diamond Cut-off wheels (Resin Bonded, high conc.) |

| DIMOS | 19-200 | ø 200 Diamond Cut-off wheels (Metal Bonded, med. conc.) |

| DIMOS | 19-205 | ø 200 Diamond Cut-off wheels (Metal Bonded, high conc.) |

| DIMOS | 19-201 | ø 200 Diamond Cut-off wheels (Resin Bonded, high conc.) |

| CBN Cutting Discs (1 pc) for Precision Cutting | ||

| CBN | 19-127 | ø 125 CBN Cut-off wheels (Metal Bonded, high conc.) |

| CBN | 19-152 | ø 150 CBN Cut-off wheels (Metal Bonded, high conc.) |

| CBN | 19-202 | ø 200 CBN Cut-off wheels (Metal Bonded, high conc.) |

| Cutting Fluid | ||

| METCOOL | 19-902 | Nature Friendly Soluble Oil, 5 lt. |

| METCOOL II | 19-905 | Nature Friendly Soluble Oil, 1 lt. |

| METCOOL-NF | 19-906 | Nature Friendly Soluble Oil, 5 lt. |

| Perfect corrosion protection for reactive metals like copper, brass, | ||

| cobalt, aluminum, tungsten carbide, etc… | ||

|

|

|

||

| Extremely Precise Cutting | Powerful and Precise Cutting Motor! | Integrated Recirculation Cooling Unit | ||

|

|

|

||

| Easy Operation With Touch Screen and Joystick | Instafeed Cutting ( Auto Feedrate) | Rapid Pulse Cutting | ||

|

|

|

||

| Laser Alignment Unit | Blade Dressing Unit | Rotation Stand |